Manure Machines | Cow Dung Dewatering | Cow Dung Dewatering Machine | Dewatering Machine

Manure dewatering Machine | Cow dung dewatering machine 3A 7 kW – The perfect organic cow dung making machine and cow dung fertilizer solution.

3A7kW full automatic cow dung waste separation machine is a device to serve the waste treatment process in the process of raising livestock such as cows, buffaloes, pigs, goats… capable of separating the collected mixed waste into separate solid and liquid form. From there, reducing the area of the storage area and saving time, cost and effort in treating livestock wastewater. Making a great contribution to ensuring sustainable development and balancing the balance between economy – environment – society.automatic

Manure Dewatering Machine | Cow Dung Dewatering Machine

Operating principle manure dewatering machine

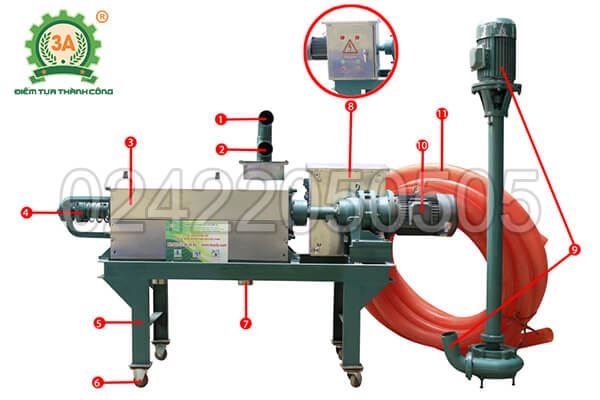

- Redundant material return tube

- Feed pipe

- Compressor and dewatering chamber

- Presser shaft and dry manure outlet

- Machine frame

- Wheels

- Sewage outlet

- Electrical cabinets

- Suction nozzle assembly and pump motor

- Presser shaft motor

- Raw material conduit

The livestock waste mixture is sucked through the suction chamber, then through the duct and transferred to the feed hopper. After the material falls into the working chamber, it will be gradually pressed by the screw shaft in the direction of the outlet. Strong compressive force from screw will quickly reduce the volume of feces, followed by the process of separating water from solid matter using automatic screw. From there solid manure and wastewater are separated.

On average, how much manure can be pressed by the 3A7kW dung dewatering screw press waste separator per hour?

Thanks to the focus on design and material selection, the engine that makes up the 3A7kW dung dewatering machine is capable of continuous and stable operation and gives an average yield of 500 – 600 kg/h cow dung. If the machine runs continuously for 8 hours a day, farmers will handle all 4-5 tons of fresh manure. This is equivalent to a reduction of 7-10 cubic meters of fresh manure during the day.

The cow dung dewatering screw equipment not only helps people save space and costs to build a tank, but also prevents the odor of pet waste from spreading and makes the wastewater treatment process simpler and easier.

How is the quality of manure and wastewater after separation?

The mixture of manure, urine, and barn washing water, after going through the 3A7kW cow dung dewatering, will produce 2 separate products:

– Dry manure has stable moisture content in the range of 30 – 50%, easy to collect, bagged, suitable for fertilizer production or as feed for worms, earthworms…

– Wastewater has a low amount of suspended solids, supporting the rear treatment process to take place faster and easier. Thereby significantly saving wastewater treatment costs and not affecting the surrounding environment.

Watch the Video for manure dewatering machines.

Get Cow Dung Dewatering Machine Price | Contact Us

Cow dung dewatering machine is widely used in many manufacturing industries such as:

– Production of organic fertilizers

– An indispensable device in the dewatering machine waste treatment system

– Making food for raising earthworms, worms…

What benefits does the 3A7kW cow dung composting machines bring to users?

– Save time and effort in separating juice from dewatering machine cow dung log waste mixture.

– Solid manure after pressing is easily bagged, preserved or moved to the place of consumption. Wastewater is easier to treat cheaper and faster.

– Protect the environment, limit pollution. Limit creating shelters for pathogens and reduce the attraction of harmful insects and animals.

– Saving land fund and cost of building storage tanks.

– No direct contact with waste is required. Ensure health and hygiene for users.

– Increase income in the process of breeding.

– Turn waste into useful products like organic fertilizer.

Cow Dung Dewatering Machine Design

What are the outstanding features of the cow dung waste separator?

- Understanding the operating principle that requires great pressure to be able to separate the most amount of water from feces, the manufacturing team used up to 2 separate motors: 4kW motor for the press shaft and 3kW for the presser shaft. suction shaft to ensure stable and continuous operation.

- The machine size is quite compact, only 2500 x 630 x 1220 mm, weighing 300kg. Below the base, there are 4 360-degree rotating wheels to help people move and navigate the device more easily.

- The machine is made of U steel, corrugated iron, stainless steel… super durable and powder coated to ensure the durability of the device as well as prevent corrosion and rust.

- Strong screw protection cap, with a handle arrangement for easy lifting and lowering.

- The machine cow dung frame is sturdy, limiting vibrations when operating.

- The machine operates fully automatically, including 2 stages: sucking materials from the tank into the machine and separating the juice from the manure. Thereby reducing labor costs to support and ensure the health of workers when limiting exposure to animal waste.

- Connecting the suction pipe to the inlet pipe is easy and flexible with screws while still being sure.

- Small size screen, filtering to remove solids mixed in wastewater, making later treatment easier.

- Water outlet and separate, separate, convenient for collection and management.

Cow Dung Fertilizer | Organic Cow Dung | Organic Fertilizer Machine

Equipment achieves high productivity, guaranteed product quality is a combination of many factors:

- Dedicated research and development team, rich in expertise, applying the most advanced technologies.

- Production line, mass production in modern factory. Not only ensuring the quality of the equipment, providing identical replacement parts, but also ensuring that you can buy the product at the lowest price.

- Dewatering screw press machine is rigorously tested before being shipped, must fully meet the following criteria: durability, output product quality, stable and continuous operation and low power consumption.

- Machine design and manufacturing service on request: we will improve and manufacture a separate dung dewatering system waste separation machine according to your individual order requirements. To best suit the current cow dung fertilizer production and breeding status of each farm.

Cow dung dewatering machine is a machine designed to remove water from cow manure, chicken manure.

This equipment is primarily utilised in the production of biogas and organic fertiliser. Cow dung is an excellent source of biomass energy, but it must be dried before use. It will not create enough bio-gas or organic fertiliser if it is not adequately dried. Cow dung dewatering machines were created to address this issue by extracting water from cow dung and drying it.

A cow dung dewatering machine can be used to convert cow dung into organic manure. It removes the water from the cow dung and leaves behind a dry, clean product which can be used in agriculture as well as for other purposes. This process is done through a series of steps where water is taken out of the material by using different methods such as centrifugation, vacuum filtration or drying process.

Dewatering machine is an equipment that is used to remove water from the slurry. The dewatering machine is made up of a suction pump or centrifugal pump. The suction pump sucks the water out and then the centrifugal pumps push it to a tank where it will be stored until it can be disposed of or reused.

Contact Us for Product Information and Price

To contact our Sales Team or Customer Care:

WhatsApp/Zalo/Line/Viber : +84 9086 35 704

Email: [email protected]

Skype: contact.rahul

WeChat: mondrahul