Stone Crusher Machine | Stone Crusher | Durable Efficient Stone Crushing

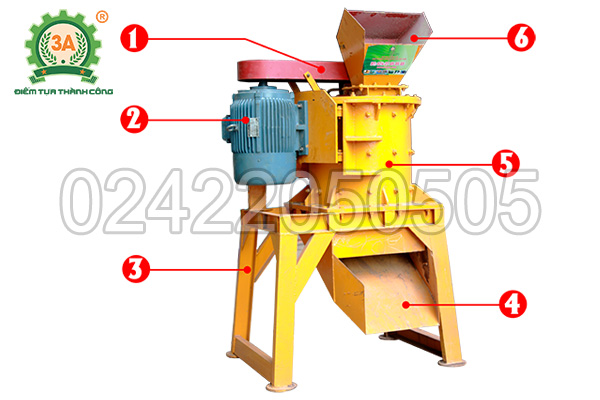

Stone Crusher Machine | Stone Crusher | Durable Efficient Stone Crushing – 3A 37 kW

The 3A37Kw Stone Crushing Machine is a product manufactured, manufactured and distributed by Tuan Tu Investment Joint Stock Company in the market. The stone crusher machinery has the feature of crushing available materials such as: Construction stones (1×2 or 3×4), broken bricks, crushed concrete, coal, cobblestone, gravel, hilly soil…. with a capacity of 2-4 tons/hour. The output material is artificial sand, which is applied in many different fields such as construction, coal, farming, brick production, etc. at construction sites, industrial parks, factories, and workshops.

Stone Crusher Machinery | Small Stone Crusher Plant for Sale

What are the benefits of 3A37Kw stone to sand crusher?

Taking advantage of scraps from construction works such as rubble, broken concrete, etc. to produce, thereby reducing the cost of materials, saving construction costs.

Taking advantage of discarded scrap to recycle as materials used in daily life is an option to protect the environment and reduce pollution.

The stone, after being crushed into small fine sand, can be mixed with cement, stone, making concrete solid, durable, the quality is not inferior to natural sand but the price is cheaper. Therefore, the mini sand stone crusher will still be an effective assistant in construction projects, limiting the exploitation of natural sand to bring positive benefits to nature.

Bricks, rubble, gravel, coal, etc., after grinding into fine sand, can be used to produce bricks, honeycomb coal… Therefore, the 3A37Kw sand crusher will be a good assistant for brick and quartz factories. honeycomb coal… immediately solve the problems of input materials and pressure on the environment.

6 outstanding features of 3A37Kw of Stone to Sand Crusher

Using the main material is solid chromium alloy, long life

3A37Kw rock crusher is a vertical shaft stone crusher . The main construction material of the machine is C45 steel and thick chromium alloy, which is cast directly at the factory by 3A’s skilled technicians through careful selection and testing processes. Therefore, this construction stone crusher has a solid structure, avoiding the impact of the external environment and the possibility of abrasion during operation.

The chassis is designed with 4 legs made of thick, solid V steel that both supports the entire weight of the machine and minimizes vibration during use.

3A37Kw stone to sand crusher with durable material. The machine is made from C45 steel and thick chromium alloy

Strong, smooth, noise-restricted engine

3A stone crusher uses a 37Kw large capacity motor, 380V 3-phase power source, 150A aptomat connected to the control cabinet to ensure the safety of the user and at the same time to help the machine run well, run smoothly, and limit the noise. ambient noise. The machine uses a powerful 37Kw motor

The system of coarse hammer and fine grinding hammer is thick and efficient

The rough hammer and fine crushing hammer system of the 3A construction stone crusher is reasonably arranged, tempered from a thick chromium alloy with high wear resistance. Especially, the inner lining of the hammer has been improved by 3A technicians with a thickness of 20mm to avoid problems when the machine is running and contribute to improving the crushing efficiency of the machine.

Crushing hammer system of stone crusher 3A37Kw. Coarse hammer and fine mill hammer system.

The coarse crushing hammer and the fine crushing hammer are divided into different stages running from top to bottom with a total of 8 coarse crushing hammers above and 48 fine grinding hammers below.

The crushing chamber of the machine works based on the method of crushing the material in the centrifugal direction running axially from top to bottom. After being fed into the upper inlet, the material will gradually descend into the crushing chamber and pass through the stages of coarse crushing hammer and fine crushing hammer.

Impact force from crushing hammer with raw material

Impact force between materials

The impact force between the material and the plate on the machine body. Therefore, the input material will be continuously crushed through different floors, the rotation speed is high, so the output product is very fine, small, uniform, the average size is from 2 to 5mm depending on the needs of use. . The stone, after being crushed into fine sand without impurities, has very good adhesion, which can replace the scarce natural sand source with low cost. Therefore, stone crusher not only helps to solve the problem of raw material scarcity, but also contributes to environmental protection.

Crushing a variety of materials, high productivity, reducing the amount of dust released into the environment.

The input materials of the crushing chamber are very diverse such as broken bricks, coal, hill soil, bricks and tiles, crushed concrete, construction stone with size 1×2 or 3×4, kaolin soil, iron ore… , investors can take advantage of a lot of available materials, scraps after demolition from construction works, houses and buildings to help reduce waste to the environment and save construction investment costs.

3A37Kw stone to sand crusher crushes a variety of materials.The mill can handle a variety of materials

3A37Kw stone to sand crusher can crush raw materials in dry and wet form. Especially when grinding materials with high moisture content, the amount of dust will be lower, limiting pollution and protecting operator’s health.

Thanks to the use of a large-capacity motor, a healthy 3-phase power source, an efficient hammer and hammer system, the 3A37Kw stone crusher has high working productivity, reaching from 2 to 4 tons/hour (depending on the size of the sand mill 3A37Kw). on the moisture and hardness of the input material). The finished product after crushing can be applied to many different industries such as construction, coal, farming, brick production… with a much cheaper price than natural sand.

High productivity 3A37Kw stone to sand crusher

3A37Kw artificial sand crusher has outstanding high productivity

Easy to clean and maintain

The motor of this construction stone crusher is reasonably designed, so it is very convenient in the cleaning process. After grinding all the ingredients, leave the machine idling and use the water hose to wash the outside and the material outlet.

For the grinding chamber, the operator only needs to disconnect the power, remove the locking pin, use water to directly clean the hammer system, then let it dry for the next grinding. 3A37Kw stone crusher is easy to clean after use

Can design the feed conveyor

At construction sites, industrial parks, factories, users can design more conveyors to transfer materials from the gathering location to the place where they need to be crushed, then bring the crushed materials to the place where they need to be used. help save time, effort, improve working efficiency.

3A – Leading Stone Crusher Machine Manufacturer unit specializing in research and manufacturing of prestigious and top quality stone crusher machines in Vietnam.

Choosing and using the 3A37Kw Stone Crushing Machine, you not only have maximum peace of mind about the quality of the product, but also receive other practical benefits such as ease of use, warranty – maintenance and convenience. Thanks to the spare parts that are always available, the nationwide system of stores and agents…

3A accepts to design and manufacture equipment on demand in large quantities. Not only providing equipment and machinery researched and produced by the company itself, 3A also accepts to design and manufacture industrial machines according to the requirements of customers in large quantities.

We can provide large quantity stone crusher machine stock.

It is not easy to answer this question because there are many factors to consider when choosing the best stone crusher.

We will try to give you an overview of the different types of stone crushers and their applications so that you can make a wise decision when buying one.

The following table compares the different stone crushers based on their strengths and weaknesses.

Stone crusher Strengths Weaknesses

1. Jaw Crusher High capacity and high production rate, easy to install, low cost High energy consumption, high maintenance costs

2. Gyratory Crusher Low installation costs, simple operation and maintenance Higher production rate with lower capacity than jaw crusher, lower feed size than jaw crusher

3. Cone Crusher Low installation costs, simple operation and maintenance Higher production rate with lower capacity than jaw crusher

Stone crusher machine is used to crush stone into small pieces.

The use of stone crusher machine is to crush stones into small pieces.

us leo.

Contact Us for Product Information and Price

To contact our Sales Team or Customer Care:

WhatsApp/Zalo/Line/Viber : +84 9086 35 704

Email: [email protected]

Skype: contact.rahul

WeChat: mondrahul